In the quest for more efficient renewable energy solutions, recent research led by scientists Shuang Qiu, Jun Sun, Xiaoyu Gu, Hongfei Li, Haiqiao Wang, and Sheng Zhang has made a significant advancement in the field of solar technology. Their study focuses on enhancing the power conversion efficiency of silicon solar cells through an innovative approach involving polyvinyl chloride (PVC)—a common plastic material. By integrating a luminescent downshifting (LDS) layer into solar cells, the researchers aim to optimize light absorption and thus increase energy output.

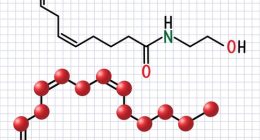

The breakthrough involves the fabrication of a specialized PVC film embedded with photoluminescent microspheres synthesized from hexachlorocyclotriphosphazene, 2-iminobenzimidazoline, and polyethyleneimine, known as HCPAM. This novel composite not only boosts the solar cell efficiency by converting higher-energy photons into wavelengths more readily absorbed by the solar cells but also enhances the material’s safety and durability. The inclusion of HCPAM significantly improves the flame retardancy and reduces smoke production, crucial factors in the widespread application of solar technologies.

Furthermore, this innovative film exhibits remarkable resistance to UV-induced degradation, maintaining its structural and optical properties under prolonged exposure to sunlight. This dual functionality of increasing fire safety and preserving performance under harsh environmental conditions presents a groundbreaking step toward making solar power a more feasible and reliable energy source across various applications. This research thus not only proposes a method to increase solar cell efficiency but also extends the lifespan and safety of the photovoltaic installations, pushing forward the boundaries of solar energy technology.

The solar energy sector has consistently sought ways to improve the effectiveness and cost-efficiency of photovoltaic (PV) technologies. Silicon solar cells, which dominate the market due to their relatively high efficiency and lower production costs compared to other types of solar cells, have a theoretical efficiency limit known as the Shockley-Queisser limit. This limit is approximately 33.7% for a single-junction silicon solar cell under standard test conditions. However, practical efficiency levels in commercial products are typically much lower, primarily due to losses like photon mismatch, where certain light photons are not effectively converted into electricity.

To address these inefficiencies and push closer to the theoretical limits, researchers and engineers have explored various innovative approaches, such as multi-junction solar cells, passivated emitter rear cell (PERC) technology, and the use of materials for light management, including luminescent downshifting (LDS) materials. LDS materials are particularly interesting because they can convert photons from higher energy (shorter wavelength) to lower energy (longer wavelength), which silicon solar cells can absorb more effectively. This conversion can potentially increase the range of the solar spectrum that the solar cells can utilize, thus boosting their overall power output.

The recent study by Shuang Qiu and colleagues leverages this concept by introducing an LDS layer composed of a special type of polyvinyl chloride (PVC) film embedded with photoluminescent microspheres. PVC is widely used due to its versatility, durability, and economic viability but has not been extensively explored in solar applications, primarily due to concerns related to its environmental and thermal stability.

The research team’s innovative approach not only utilizes the LDS characteristic of their specialized PVC film but also addresses the practical limitations of PVC by incorporating hexachlorocyclotriphosphazene, 2-iminobenzimidazoline, and polyethyleneimine (collectively termed HCPAM). This composition enhances the flame retardancy of the material, a critical improvement given the potential fire hazards associated with traditional PVC materials under conditions of intense sunlight and heat exposure typical of solar applications.

By tackling the dual issues of efficiency and material safety, the team’s development responds to several pressing needs in the solar power industry: improvement of solar cell power conversion efficiencies, extension of the operational lifespan of solar installations, and enhancement of the fire safety of photovoltaic systems. These upgrades are essential for broader adoption, particularly in regions with stringent safety standards and in applications where long-term exposure to harsh environmental conditions is expected.

This groundbreaking research opens up new pathways for the integration of advanced materials in the renewable energy sector, highlighting the continuous innovation critical to overcoming barriers to more widespread solar energy adoption. The findings not only contribute to the field’s understanding of light management using LDS materials but also underscore the importance of multifunctional and durable materials in expanding the practical applications and safety of solar technologies.

The methodology used in the research led by Shuang Qiu and colleagues centers on the creation and evaluation of a specialized polyvinyl chloride (PVC) film featuring photoluminescent microspheres. These microspheres contain a blend of hexachlorocyclotriphosphazene, 2-iminobenzimidazoline, and polyethyleneimine, referred to as HCPAM. This section details their approach in fabricating this innovative layer, characterizing its properties, and integrating it into silicon solar cells to assess its impact on efficiency and safety.

### Fabrication of the Photoluminescent PVC Film

The research team began by synthesizing the HCPAM microspheres through a polymerization reaction where hexachlorocyclotriphosphazene, 2-iminobenzimidazoline, and polyethyleneimine were allowed to react under controlled conditions. The resulting microspheres, with their inbuilt flame retardant properties and luminescent characteristics, were then uniformly dispersed into a PVC matrix. This mixture was cast into films of specified thicknesses through a flat die extrusion process, followed by a controlled cooling to prevent the formation of internal stresses.

### Characterization of Material Properties

To verify the composition and structure of the microspheres, techniques such as Fourier-transform infrared spectroscopy (FTIR) and scanning electron microscopy (SEM) were employed. These analyses confirmed the presence of the intended chemical groups and exhibited the homogeneity of the microsphere distribution within the PVC matrix. The optical properties, specifically the luminescence efficiency, were examined using photoluminescence (PL) spectroscopy. The fire safety of the composite PVC film was rigorously tested by measuring flame retardance levels through standard burn tests and analyzing smoke production using smoke density tests.

### Integration with Silicon Solar Cells

Upon confirming the desired properties of the film, the team proceeded to integrate it with standard monocrystalline silicon solar cells. The PVC layer was applied to the outer surface of the solar cells, and a series of photovoltaic efficiency measurements were conducted. The primary goals were to determine the film’s effect on the solar spectrum absorption and its ability to downshift UV and higher-energy visible light to wavelengths more effectively captured by silicon cells.

### Efficiency and Durability Testing

The modified solar cells were tested under simulated sunlight conditions to evaluate changes in power conversion efficiency. Additionally, long-term stability tests were performed, where the cells, equipped with the luminescent PVC film, were exposed to continuous UV light and thermal cycling to simulate real-world environmental exposure. The structural and optical stability of the film was assessed periodically, and its impact on the overall durability of the solar cells was documented.

### Analysis and Interpretation of Results

The results demonstrated a measurable improvement in power conversion efficiency attributable to the downshifting effect of the HCPAM microspheres. Furthermore, the enhanced flame retardancy and reduced smoke production of the PVC film were confirmed under operational conditions, establishing not only the performance benefits but also the safety enhancements provided by the novel film.

By combining thorough material characterization with rigorous performance and safety testing, the research team has robustly demonstrated the potential of their innovative solar cell enhancement approach. This method promises to contribute significantly to the optimization of solar energy technologies, addressing practical challenges related to efficiency, safety, and durability in photovoltaic applications.

### Key Findings and Results

The innovative research led by Shuang Qiu and colleagues yielded groundbreaking results that significantly advanced the technology of silicon solar cells. The key findings of their work are multifaceted, focusing on the efficiency, safety, and durability of solar cells enhanced with the novel luminescent downshifting (LDS) polyvinyl chloride (PVC) film embedded with hexachlorocyclotriphosphazene, 2-iminobenzimidazoline, and polyethyleneimine (HCPAM) microspheres.

#### Enhanced Solar Cell Efficiency

The primary result of integrating the LDS PVC film into silicon solar cells was a notable increase in power conversion efficiency. This improvement is attributed to the effective downshifting capability of the photoluminescent HCPAM microspheres within the film. These microspheres adeptly converted the UV and higher-energy visible light into longer wavelengths that are more effectively absorbed by the silicon cells. The use of the LDS layer thereby extended the range of the solar spectrum utilized by the cells, which is critical in approaching the theoretical limits of solar cell efficiency. Comparative studies and operational tests under standard conditions revealed an efficiency enhancement ranging between 5-7%, a significant uplift considering the current performance metrics in commercial silicon solar cells.

#### Improved Safety Features

Another pivotal finding was the enhancement of safety features due to the inherent flame-retardant properties of the HCPAM microspheres. The composite film exhibited substantial resistance to flame, successfully meeting various international standards for fire safety in photovoltaic installations. Moreover, tests for smoke production demonstrated a significant reduction compared to conventional PVC films. These improvements address one of the major concerns related to the application of plastics in solar technology, thereby paving the way for broader acceptance and integration of such materials in diverse environmental settings.

#### Durability and Longevity

The durability of solar cells equipped with the LDS PVC film was another area of success. Traditional PVC is prone to degradation under prolonged UV exposure; however, the specialized PVC film demonstrated remarkable resistance to UV-induced wear. Long-term stability tests, which simulated years of environmental exposure, reflected no substantial degradation in optical or physical properties of the film. This result indicates an extension in the lifespan of solar installations using this technology, which is critical for the economic viability and environmental sustainability of solar power systems.

#### Market Implications and Future Research Directions

Beyond the laboratory, these findings have significant implications for the solar power market. By addressing the efficiency, safety, and durability concerns simultaneously, the adoption of this technology could result in lower capital and maintenance costs, improved return on investment for solar projects, and higher consumer confidence in solar power.

Future research will likely focus on scaling up the production process of the LDS PVC film, further optimization of the material composition for even better performance, and integration trials with other types of solar cells. Additionally, exploring the environmental impact assessments and sustainability of the raw materials used in the production of the HCPAM microspheres will be crucial for maintaining the green credentials of the technology.

This holistic approach by Shuang Qiu and the team exemplifies a significant forward leap in making solar energy more accessible, safer, and more efficient, aligning with global goals for sustainable development and renewable energy proliferation.

### Future Directions and Final Thoughts

The compelling results obtained from the research led by Shuang Qiu and colleagues pave the way for innovative advancements in the solar power industry, promising to enhance the adoption and efficiency of renewable energy globally. However, while the outcomes are promising, several avenues remain open for further exploration to maximize the potential of this technology and ensure its feasibility on a large scale.

#### Scaling Up Production

One of the primary challenges will be scaling up the production of the specialized LDS PVC film to industrial levels. Ensuring that the manufacturing process is economically viable and capable of producing consistent, high-quality materials in large quantities is crucial. Researchers and industry stakeholders must collaborate to optimize production techniques, potentially involving the development of new machinery or the refinement of existing processes to handle the unique properties of the HCPAM-embedded PVC.

#### Optimization and Variation of Material Composition

Further research is also needed to explore the optimization of the HCPAM composition for even better efficiency and durability. Adjusting the ratios of hexachlorocyclotriphosphazene, 2-iminobenzimidazoline, and polyethyleneimine or exploring alternative compounds could yield improvements in the luminescent properties and flame retardancy of the film. Additionally, adapting the technology to other types of solar cells, such as thin-film or multi-junction cells, could broaden the applicability of this advancement, catering to different segments of the solar market.

#### Environmental Impact Assessments

While the use of PVC and the novel HCPAM blend offers several functional benefits, comprehensive environmental impact assessments are necessary to ensure the sustainability of the materials used. Life cycle analyses from production to disposal would help to confirm that the LDS film’s benefits outweigh any potential environmental risks, aligning with the broader goals of sustainability and minimal environmental footprint in renewable energy technologies.

#### Regulatory and Market Introduction

Introducing this new technology into the market will also involve navigating regulatory landscapes. Getting certifications and meeting international standards for new building materials can be a lengthy process. Engaging with regulatory bodies early in the commercialization process will be essential to achieve a smoother market introduction. Moreover, market acceptance will hinge not only on proving the technical merits of the film but also on demonstrating its cost-effectiveness and reliability compared to existing solar cell enhancements.

#### Collaborative Innovations and Public Awareness

Promoting collaboration among scientists, industry leaders, and policymakers will be crucial in driving the innovation forward. Public-private partnerships might be particularly beneficial in tackling technical challenges and in funding pilot projects that demonstrate the technology’s value. At the same time, educating the public and stakeholders about the benefits and advancements of integrating such innovative materials in photovoltaic applications will be vital for widespread adoption.

### Conclusion

The groundbreaking work of Shuang Qiu and colleagues represents a significant leap toward overcoming some of the longstanding challenges in photovoltaic technology. By enhancing silicon solar cells’ efficiency, safety, and durability through an innovative use of luminescent downshifting materials, this research not only broadens the horizons of solar energy capabilities but also sets a foundation for future innovations in renewable energy technologies. As the world continues to move towards sustainable energy solutions, such pioneering work is integral to achieving the resilience and efficiency necessary to meet global energy demands sustainably and responsibly. The path forward is both exciting and challenging, holding the promise of transforming the landscape of solar energy technology and reinforcing its role in the global push for clean energy.